Integrating mechanical and hydraulic systems – how to optimise performance

There are many challenges facing engineers in the mobile and marine sectors, not least of which is the often-complex combination of mechanical and hydraulic systems, with competing priorities of machine performance, and efficiency and cost-effectiveness.

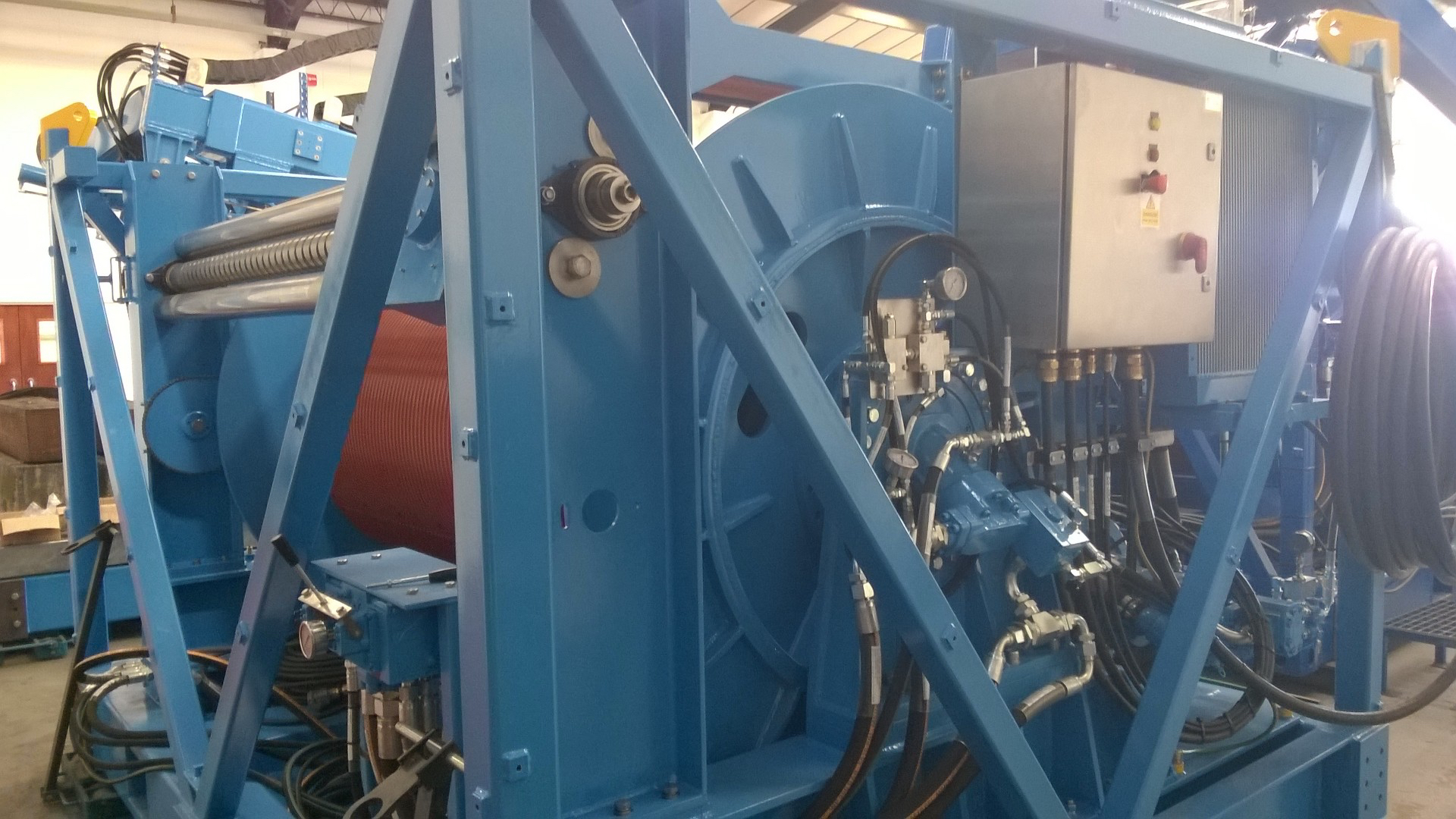

Launch and recovery system

Commonly, the specification of the mechanical components influences the hydraulic requirements, and vice versa. For example, the combination of a gearbox ratio with hydraulic motor displacement gives different flow and pressure requirements. Often, using a higher gear ratio – without any additional cost implications – allows for a reduction in motor size, saving on cost without compromising on performance. Similarly, the control of hydraulics can affect mechanical systems, e.g. where pressure relief settings of pumps and valves need to be set at a level to protect the mechanics. Clearly, a knowledge and appreciation of both areas assists in specifying a safe and efficient system, with optimised performance.

With an unrivalled breadth of engineering expertise, Brevini UK offers comprehensive support and advice to their OEM customers, through their vast range across both hydraulic and mechanical components – all aimed at optimising machine design.

In the maritime sector, looking at a large marine winch, OEMs will routinely need a slew bearing with multiple drives, meaning that there are a number of variables where adjustment can optimise performance. The slew ratio, the number of drives, the gearbox ratio and the motor displacement all need consideration. Having one supplier who can advise and supply slew bearings, slew gearboxes with pinions and the hydraulic motors can simplify the specification, reducing the engineering time considerably. And, when the supplier can also supply control valves and pumps, and optimise the hydro mechanical system, then there is added potential for greater performance or cost reduction on the whole system.

Drilling machine solutions

Brevini UK works closely with their OEM customers to gain a comprehensive understanding of their machines and their requirements. Brevini’s consultative and collaborative approach to all projects, when combined with their vast product range, presents a compelling argument to OEMs to work with one supplier, across mechanical and hydraulic systems, offering a range of benefits in an increasingly competitive market.