Repair and refurbishment: the value of Dana’s combined approach for the construction industry

Working across sectors as varied as quarrying, marine and food manufacturing, Dana’s servicing team’s 30-plus years of engineering expertise means time- and cost-savings when it comes to critical machinery repair and refurbishment. Here, Andrew Baggaley gives an overview of Dana’s approach to one project for the construction industry.

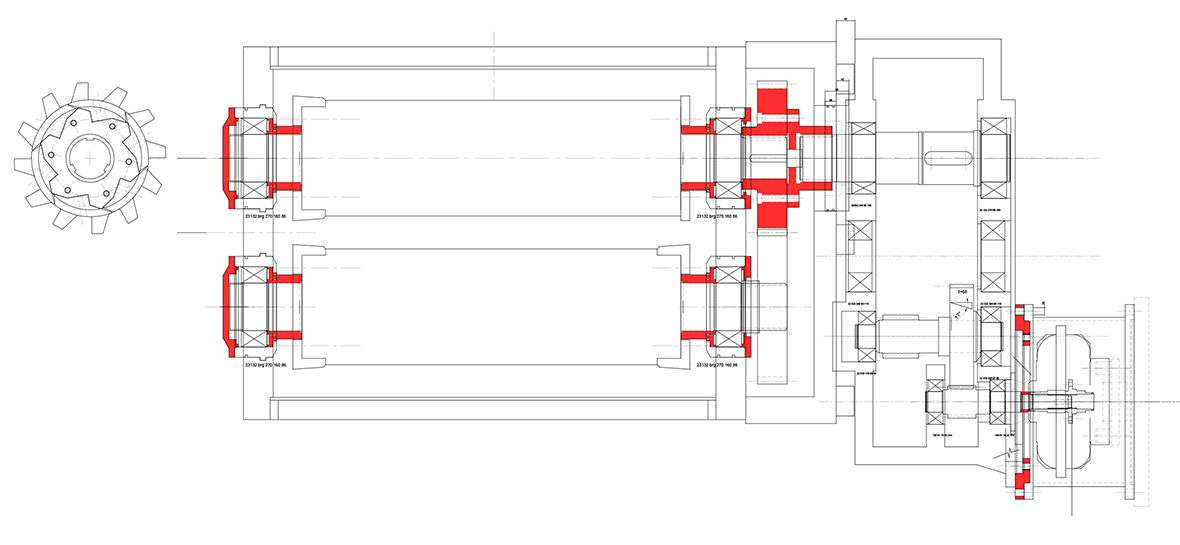

Image 1 – General arrangement of the unit

Dana were called on to bring their gearbox expertise to the repair and refurbishment of a brick crusher used by one of the UK’s largest brick manufacturers, a company specialising in high quality, durable bricks for commercial, retail and residential property development. Image 1 shows the general arrangement of the unit, and Andrew explains the engineering problems with the existing crusher,

Image 2 – Splines to the driven crusher shaft were destroyed, requiring an alternative interface to save this high value component

“The equipment consisted of a conventional gearbox with a specialist crusher frame consisting of a pair of contra-rotating shafts clad with picks. When functioning correctly, material is fed into the in-running gap and is broken down into smaller pieces. The gearbox drives the lead shaft and two spur gears synchronise the pair sharing the power. When our team examined the unit, we found that several major parts had been destroyed. The driven crusher shaft had lost the splined interface with its timing gear (image 2).

Image 3 – The replacement timing gear, which transmits drive to the crusher shaft was made with revised hub detail, three keys and a carefully controlled shrink fit were employed.

The shaft itself is a large piece of steel with a lot of machined features – an expensive item to replace, and so we were keen to save what was an otherwise-serviceable part. To do so, we decided on a keyed fit with three keys at 120 degrees and an interference fit (shown in image 3). The timing gears were worn, but we were able to take the secondary item and turn it to its better flank and reuse it.

Images 4 and 5 – Boring of the timing gear casing to realign the main bearing / cassette assemblies

The replacement for the scrapped item was made to suit the centre distance and modified to limit the backlash that would be caused by wearing it in with its mate. The whole interface between the output shaft and the crusher was badly worn, requiring re-boring (shown in images 4 and 5) and new oversize bearing cassettes to the driven end of the crusher frame.”

For this project, as with all work undertaken by Dana SAC UK’s servicing team, their engineers focused on minimising disruption to and delay in the end use manufacturing process. Reusing parts where possible meant cost was kept to a minimum as well as avoiding unnecessary delays with manufacture of new parts. Similarly, where replacement parts were required, having an inhouse manufacturing facility enabled Dana’s engineers’ drawings for bespoke parts to be tooled and supplied to the customers’ site in a timely manner. Andrew comments,

“With this project, there were a range of issues with the original parts – due to wear and to age – and some of these were potentially very expensive for the customer. Our approach is always to start with the customer’s business needs and adapt our solution, for each project. The outcome we achieved for the customer, a mix of refurb and replacement, gave them the best possible solution with minimal disruption.”

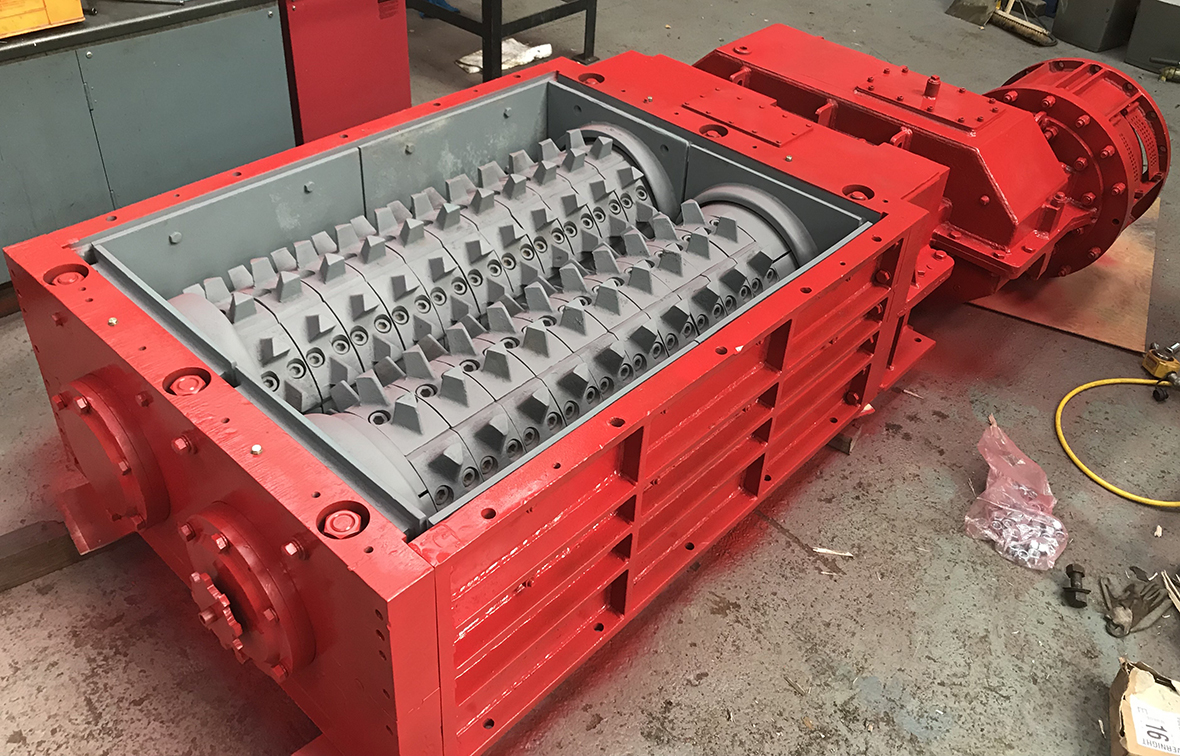

Image 6 – Built and tested gearbox and crusher frame completed with new picks