Eisenbeiss Gearbox, overhaul and reverse engineering, TATA steel works

Eisenbeiss Gearbox, overhaul and reverse engineering, TATA steel works

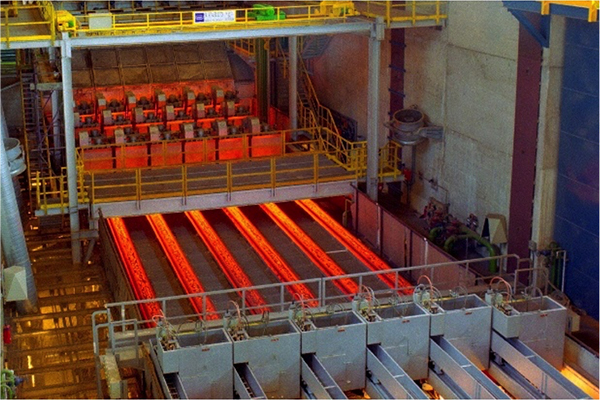

British Steel Continuous Casting

Project details

| Client: | British Steel |

| Application: | Continuous casting |

| Gearbox: | Eisenbeiss |

| Reported Problem: | Failure intervals (MTBF) <6 months. Unplanned gearbox removal costs in excess of £40,000 |

| Considerations: | Gearbox installation in an ambient operating temperature in excess of 500°C |

| Brief: | Reduce costs by Improving MTBF |

| Result: | Improved working practices, OEM bearings & reversed engineered parts now see MTBF increased to over 18 months |

| Cost savings: | Estimated over £400,000 in unplanned removal costs PA |

Gearbox in-situ & as received

Casting floor

Received condition

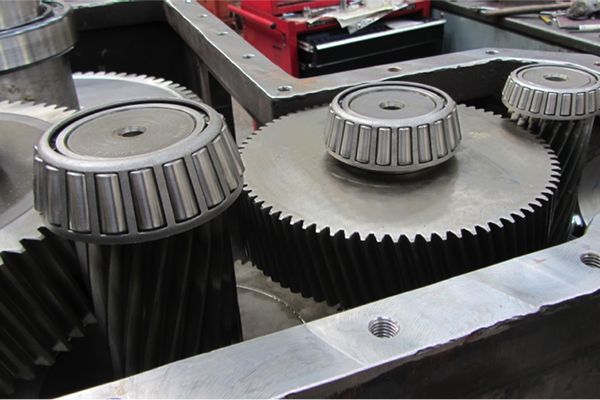

Gearbox overhaul

Gearbox internals, as received

Gearbox under re-build

Completed overhaul

Reverse engineered internal components

Completed gearbox overhaul, painted with heat resistant, reflective paint