Flender Helical Reducer, refurbishment and replacement, E.On cooling tower

Flender Helical Reducer, refurbishment and replacement, E.On cooling tower

Project details

| Client: | E.On UK Plc (Killingholme Power Station) |

| Application: | Horizontal Cooling Tower Bank (4 fans per cell, 4 cells per bank = 16 units) |

| Gearbox: | Flender Helical Reducer Type S0ND250 |

| Reported Problem: | Oil leakages and concerns over general condition for such critical components |

| Scope of work: | Initial solution proposal for removal, refurbishment and re-installation of gearboxes. Supply of risk assessment and method statements covering all onsite work. Disassembly of cooling tower fan, removal of gearbox, refurbishment of gearbox, re-installation and assembly of cooling tower fan. |

| Timescales: | Onsite disassembly and removal = 1 week Gearbox refurbishment = 2 weeks Onsite assembly = 1 week |

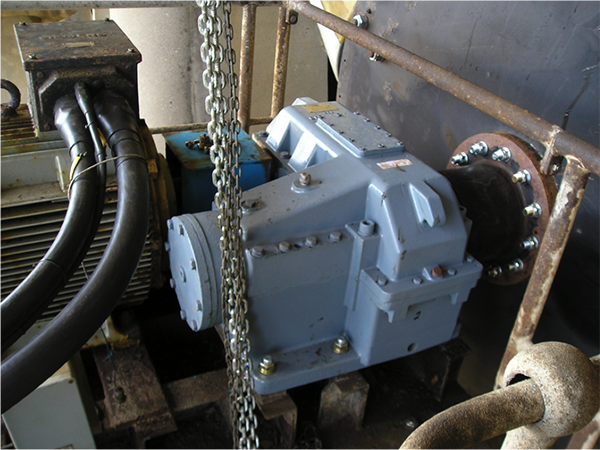

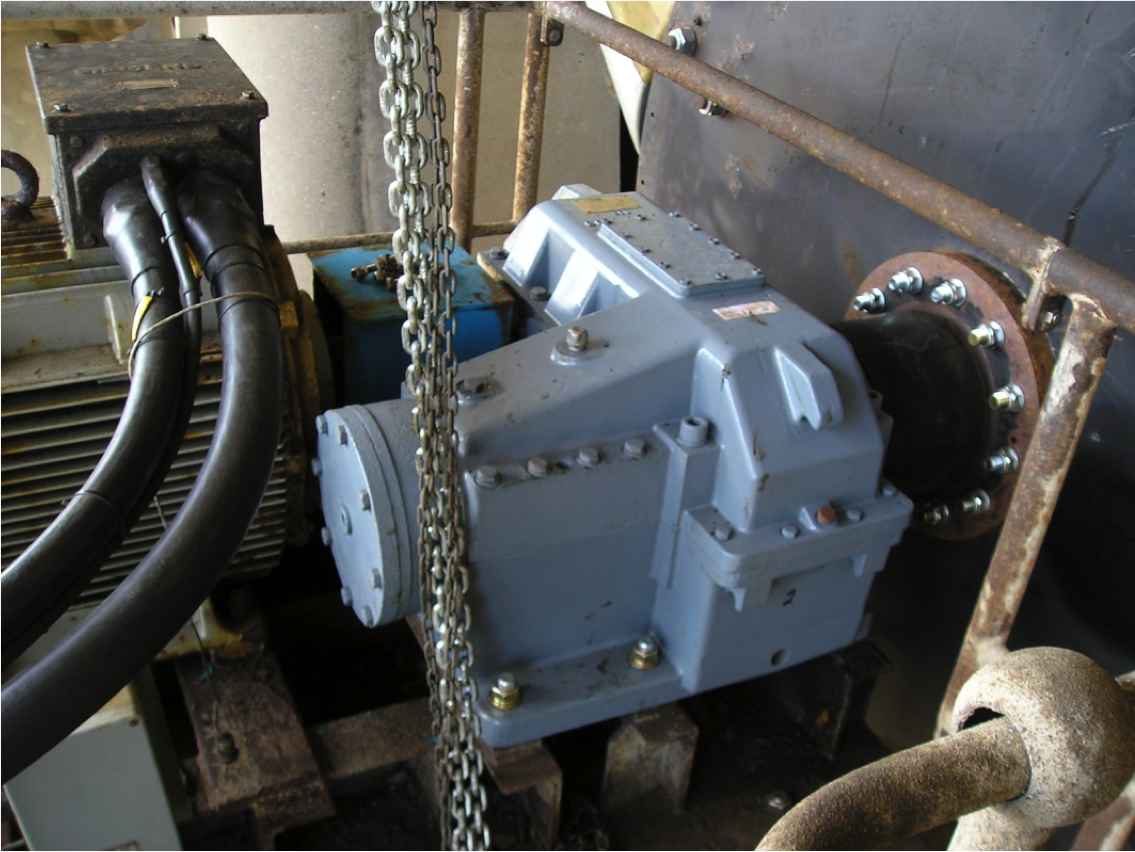

Cooling cell

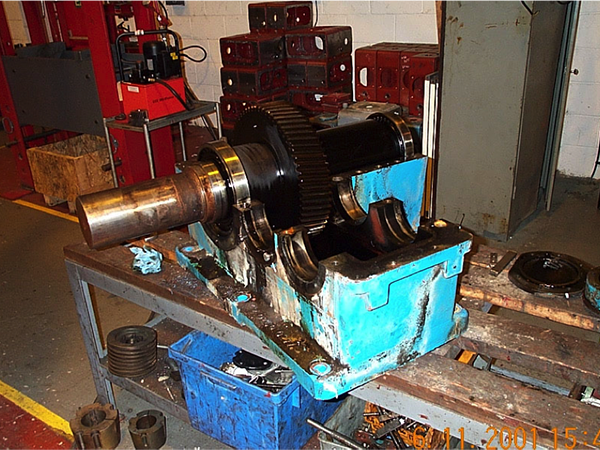

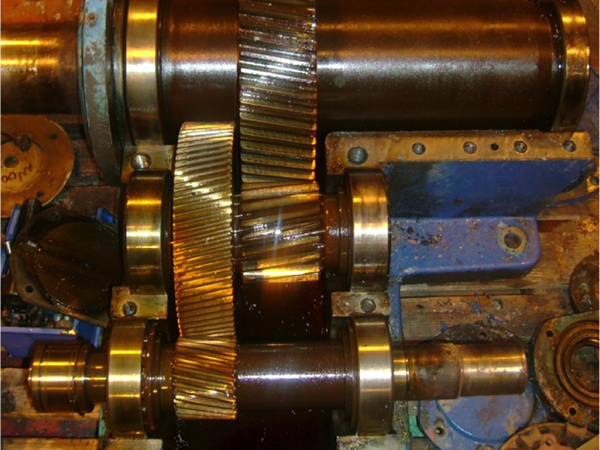

Gearbox refurbishment

Refurbished drive